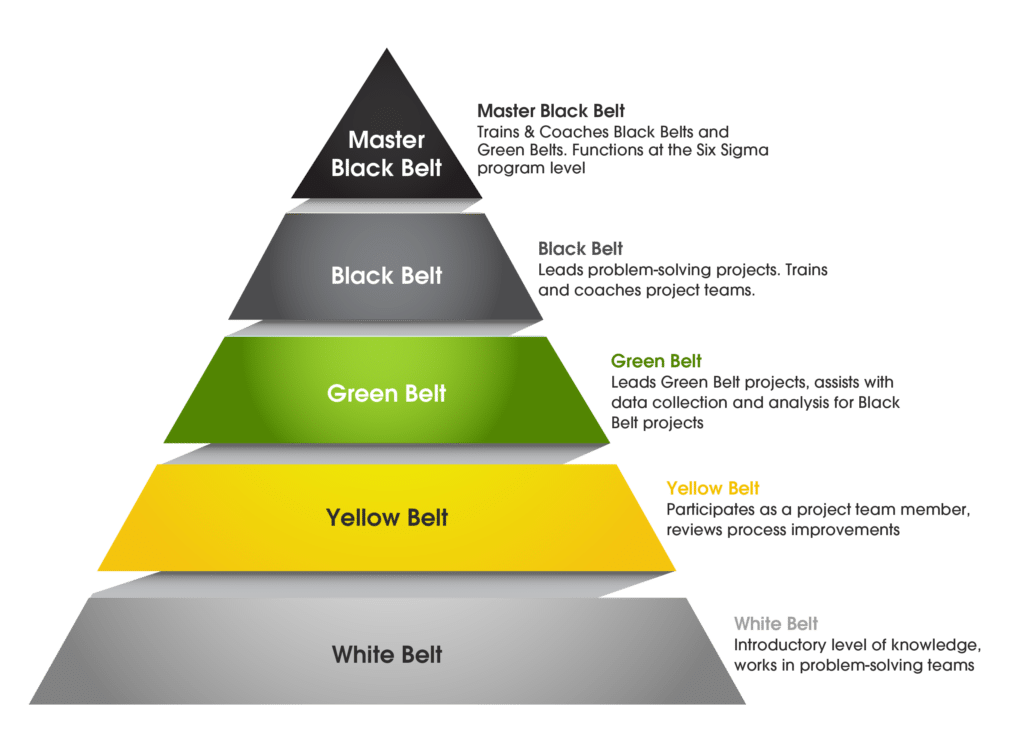

Six Sigma White Belt It is the basic level of certification that deals with the basic Six Sigma concepts. If you want to become a certified Lean Six Sigma professional check out our Lean Six Sigma certification courses accredited by IASSC.

Six Sigma Belts Lean Six Sigma Sigma Black Belt

Six Sigma Belts Lean Six Sigma Sigma Black Belt

These levels guide Six Sigma practitioners in their quest to create better and more efficient processes.

Six sigma levels. In percentages that means 9999966 percent of the products from a Six Sigma process are without defect. A sigma is a measure of standard deviation abbreviated as small s or the Greek letter σ. Training usually lasts just a few hours.

In more detail Six Sigma Green Belt typically works part-time on Six Sigma projects. Sigma Performance Levels One to Six Sigma. Any newcomer can join.

Defects or Errors Per Million Opportunities DPMO Yield or Produced or Delivered Correctly 1. Sigma Levels are the crux of the Six Sigma problem-solving approach. People work with teams on problem-solving projects.

Increasing a process levels ie. At just one sigma level below5ς or 9997 percent. Functions more at the Six Sigma program level by developing key metrics and the strategic direction.

Lean IT Certification Training. While they may work full-time on a complete business process they will only devote 20-50 of their time to the project itself. Six Sigma Yellow Belts.

Its a Lean Six Sigma metric that measures the error rate of a process based on the DPMO estimate. Six Sigma derives from statistical process modeling in manufacturing. At the project level there are master black belts black belts green belts yellow belts and white belts.

The Sigma Level estimate is a long-term estimate of the process including a potential 15 sigma shift that could occur over longer periods of time. Six Sigma Green Belts The first certification level you will experience the greatest reward at is achieving a Green Belts. These certifications can be obtained through an accreditation body like the American Society for Quality ASQ.

Trains and coaches Black Belts and Green Belts. Six sigma levels are gaining popularity in various sectors with its a significant role. Something that is within -6s Six Sigma from the centerline of a control chart was created by a process that is considered well controlled.

The Six Sigma training levels conform to specified training requirements education criteria job standards and eligibility. Six Sigma White Belts understand basic vocabulary and fundamental concepts of the methodology. These people conduct projects and implement improvements.

Acts as an organizations Six Sigma technologist. White Belt Yellow Belt Green Belt Black Belt and Master Black Belt. Training usually lasts a couple of days.

Six Sigma Yellow Belts have been trained to be a part of a Six Sigma team. Six Sigma Yellow Belts understand. What is Six Sigma level.

The participant is required to understand the basic Six Sigma concepts. Six Sigma emphasizes cycle-time improvement while at the same time reducing manufacturing defects to a level of no more than 34 occurrences per million units or events. Reducing its variability and ability to produce errors is the root of Six Sigma.

Sigma Level Table Six Sigma Digest Sigma Level DPMO Yield Defect Rate DPMO Yield Defect Rate 1 317310 682690000 317310000 697612 3023880 6976120 11 271332 728668000 271332000 660082 3399180 6600820 12 230139 769861000 230139000 621378 3786220 6213780. Technically in a Six Sigma process there are only 34 defects per million opportunities. Its an overview training level suitable for everyone within a company practicing Six Sigma.

Their roles and responsibilities are helpful during six sigma improvement projects. The Six Sigma certification comes in various skill levels. This is the simplest stage where.

Six Sigma Levels.