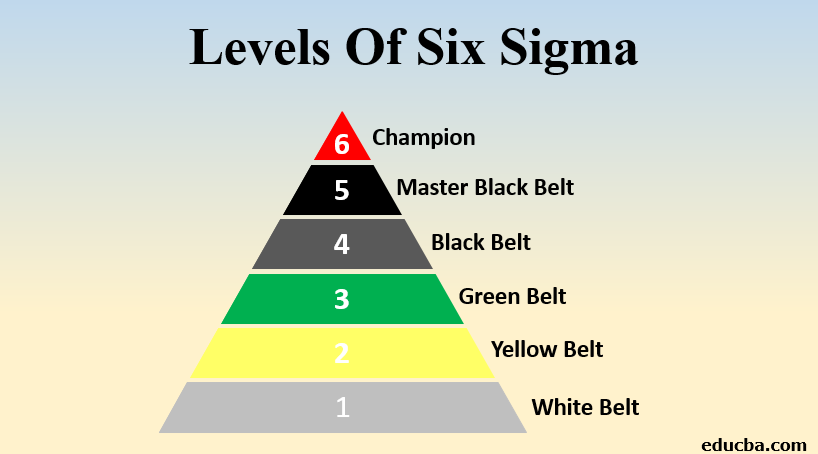

That feels like an accomplishment. Six Sigma is a disciplined data-driven approach and methodology for eliminating defects driving toward six standard deviations between the mean and the nearest specification limit in any process -- from manufacturing to transactional and from product to service.

50 Six Sigma Training Ideas Sigma Lean Six Sigma Train

50 Six Sigma Training Ideas Sigma Lean Six Sigma Train

And by using Six Sigma Motorola became a Quality leader also won the prestigious Malcolm Baldrige National Quality Award in 1988 after that the secret of Motorolas success became public knowledge and then onwards Six Sigma revolution was started.

What is 6 sigma. Six Sigma is a continuous process improvement methodology based on statistical concepts. It was introduced to our mainstream business culture in the 1980s when Bill Smith an engineer for Motorola first introduced the concept. Six Sigma is a framework that was designed to eliminate waste and improve the customer experience.

Six Sigma 6σ is a set of tools and techniques developed by Motorola engineer Bill Smith for process improvements. Six Sigma is a defined and disciplined business methodology to increase customer satisfaction and profitability by streamlining operations improving quality and eliminating defects in every organization-wide process. Six Sigma is a set of management tools and techniques designed to improve business by reducing the likelihood of error.

After Motorola many companies like Allied signal General electric implemented this methodology and produced. The philosophy behind Six Sigma is to identify removeimprove the processes that cause defects in manufacturing or business processes. Six Sigma is a set of methods and tools for business process improvement and quality management.

All the companies use a set of tools and techniques to improve product quality remove defects and assure superior quality. Then they are skilled enough to eliminate risks and errors. Its name refers to a statistical concept on the number of defects per million repetitions of a process or outputs of a product.

Six sigma was first introduced within Motorola in 1986. The smart guy will outsmart himself. Six Sigma and DMAIC Methodology Overview What is Six Sigma.

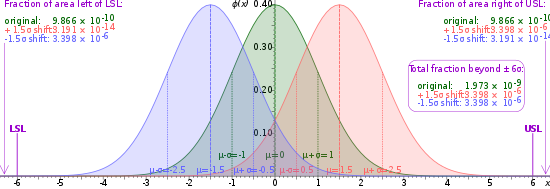

Six Sigma is a structured methodology for improving the quality of products services and processes by reducing variation with a goal of reaching less than 34 defects per million opportunities to have a defect. Its designed to increase company profitability through. Six Sigma is a goal to work towards the ideal low level of variations and defects per million opportunities DPMO.

Six Sigma is a data-driven methodology that provides tools and techniques to define and evaluate each step of a process. Six Sigma is a quality-control methodology developed in 1986 by Motorola Inc. This set of tools and techniques is known as six sigma certifications.

Lean Six Sigma is one of the most powerful problem-solving and continuous improvement methodologies because it identifies the characteristics of the real problem. The method uses a data-driven review to limit mistakes or defects in a corporate or business. Specification Limits are derived from the customer requirements and they specify the minimum and maximum acceptable limits of.

Six Sigma stands for 6 standard deviations 6σ between avarage and acceptable limits LSL and USL stand for Lower Specification Limit and Upper Specification Limit respectively. The lucky guy will. The Six Sigma certified professionals are expected to identify the risks and defects.