Free six sigma calculator which combines multiple tools into one. The main concept of Six Sigma certification is not only getting certified with Six but its all about how you can apply the tools.

Understanding Process Sigma Level Process Central

Understanding Process Sigma Level Process Central

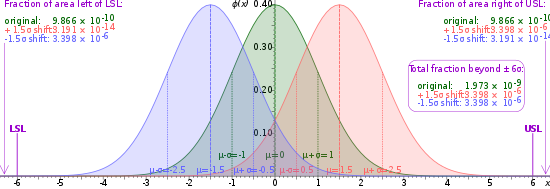

In a 6σ process 999996 of the packages are delivered correct.

Six sigma value. 6 Sigma 34 DPMO 9999966 defect-free. The action must somehow change the product or service in some manner. Cpk or 133 indicates that the process is capable and meets specification limits.

The aim of Six Sigma is to make a process effective with - 9999996 defect-free. Identify the process and process boundary. This means a six sigma process produces 34 defects per million opportunities or less as a result.

Online sigma calculator for use in process control and quality assurance in industrial applications as well for overall business project management. The next table shows the relation between sigma values Defects Per Million Opportunities and correct items Yield. Six Sigma points to the fact that mathematically it would take a six- standard-deviation event from the mean for an error to happen.

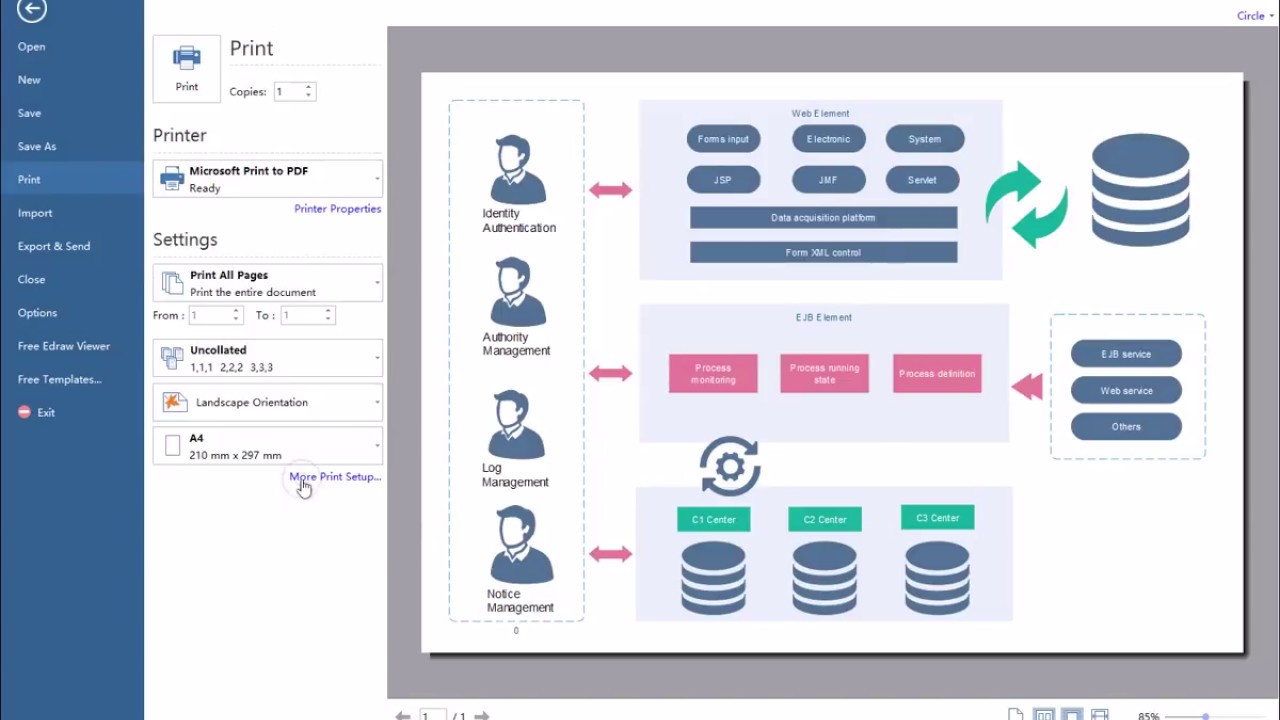

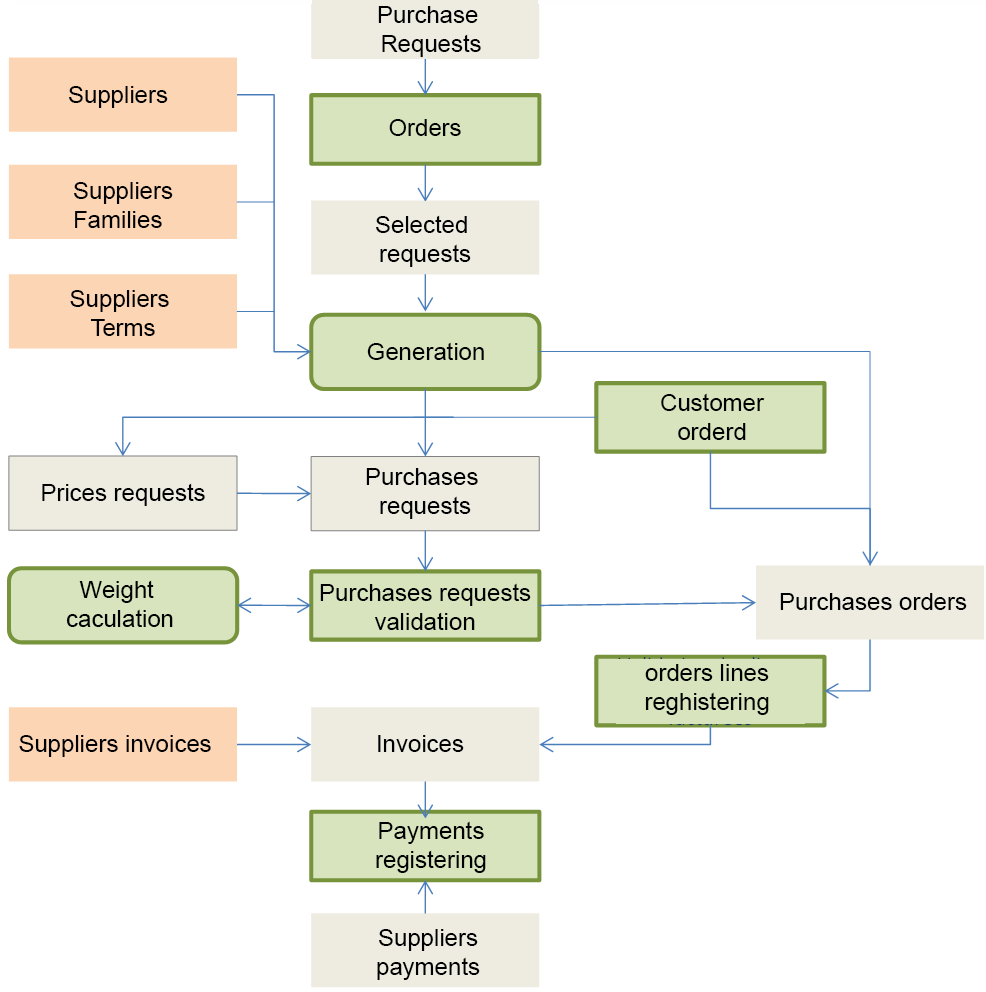

Identify the process improvement team. In layman terms it clearly showcases the flow of goods from third-party vendors to customers through your organization. Value is only relevant at a specific price and point in time.

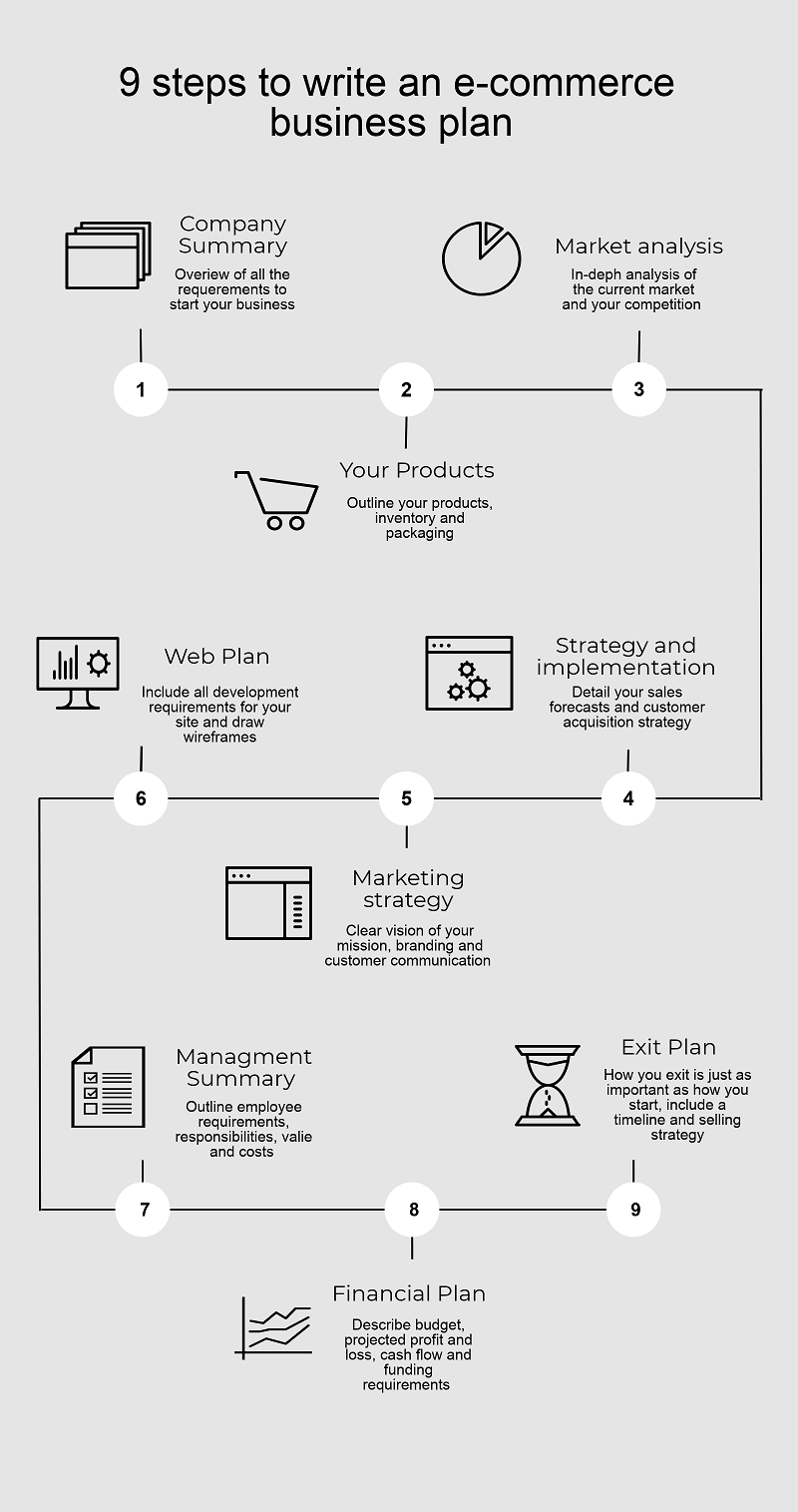

The Goal of Six Sigma. Sigma process levels 1-6 have a theoretical defect rate that is set as follows. To be a value-added action the action must meet all three of the following criteria.

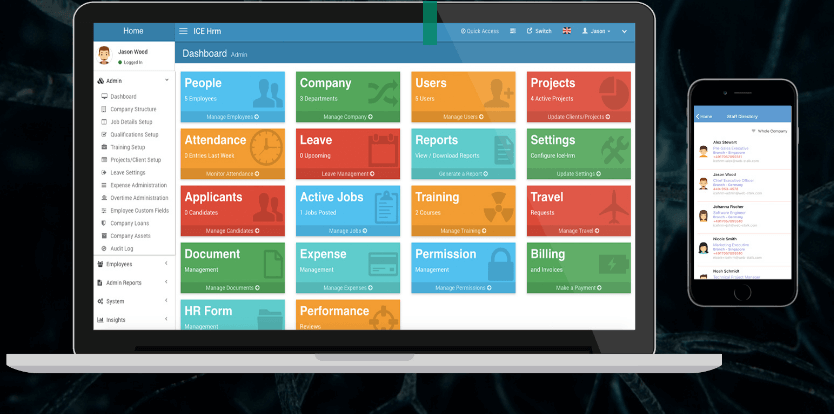

Any value less than this may mean variation is too wide compared to the specification or the process average is. Calculates defects per million units DPM percent defects from all opportunities standard yield rolled. Problem-solving in Six Sigma is done using the DMAIC framework.

Definition of Value-Added VA. 1 Sigma 691462 DPMO 3085 defect-free. The customer is willing to pay for this activity.

3 Sigma 66807 DPMO 93319 defect-free. Because only 34 out of a million randomly and normally. Value stream mapping is one of the key Lean Six Sigma toolstechniques used to provide a detailed visualization of processes in an organization.

Six Sigma is a structured problem-solving methodology. 2 Sigma 308538 DPMO 69146 defect-free. The certification is worthless if you cannot use the tools effectively and make a meaningful impact on your organization.

The team draws the current state process map in flow-chart or swim lane style. You will need to look for the 7 elements of waste and when categorizing. DPMO calculator DPM calculator RTY calculator sigma level calculator.

It must be done right the first time. A 6σ process is defined as a high quality process. Steps to create a Value Stream Map.

In order to achieve Lean thinking you must start by defining the value of the product or service in the eyes of the customer. Value of Six Sigma. In other words p Z.

With a six sigma project the process can be improved. 5 Sigma 233 DPMO 99977 defect-free. Use Z-table to see the area under the value x In the Z-table top row and the first column corresponds to the Z-values and all the numbers in the middle corresponds to the areas.

Sigma Performance Levels One to Six Sigma. In this process 691 of the packages are delivered correct. 4 Sigma 6210 DPMO 99379 defect-free.

For example a Z-score of -153 has an area of 00630 to the left of it. Identify the focus of the process improvement as defined in the Project Charter. Lean Six Sigma value a key part of lean thinking may be defined a number of equivalent ways depending on context.

Defects or Errors Per Million Opportunities DPMO Yield or Produced or Delivered Correctly 1.